Floating Floor Vibration Isolation of Recording Studios, The Farm Studios – London

Mason UK were specified to provide acoustic products and systems for the new Farm Studios on Newman Street in Central London. We worked on the design team, designing and installing the Mason FSN jack up floating floor system and supplying several other acoustic products to isolate the walls and ceilings on this highly specified project.

This project was not the normal run of the road jack up floating floor system. To start with the existing hollow pot construction of the structural slab meant that 10mm thick spreader plates were required at the jack locations. Between the plates, polystyrene void former was laid to keep the concrete thickness to a minimum and reduce the loading on the structural slab. The floating floor slabs were formed with steel angles with rockwool to the inside. The introduction of the angle protected the air gap from the ingress of builders materials.

At the last minute the client requested the installation of rebates with the floating floors to allow for cable runs. The above photo shows a suspended shutter tied in place to the reinforcing steel to provide the rebate for the cable runs.

Mason worked quickly on this project. From start to finish our duration on site was less than 2 weeks, which included the curing time for the concrete prior to the floors being jacked.

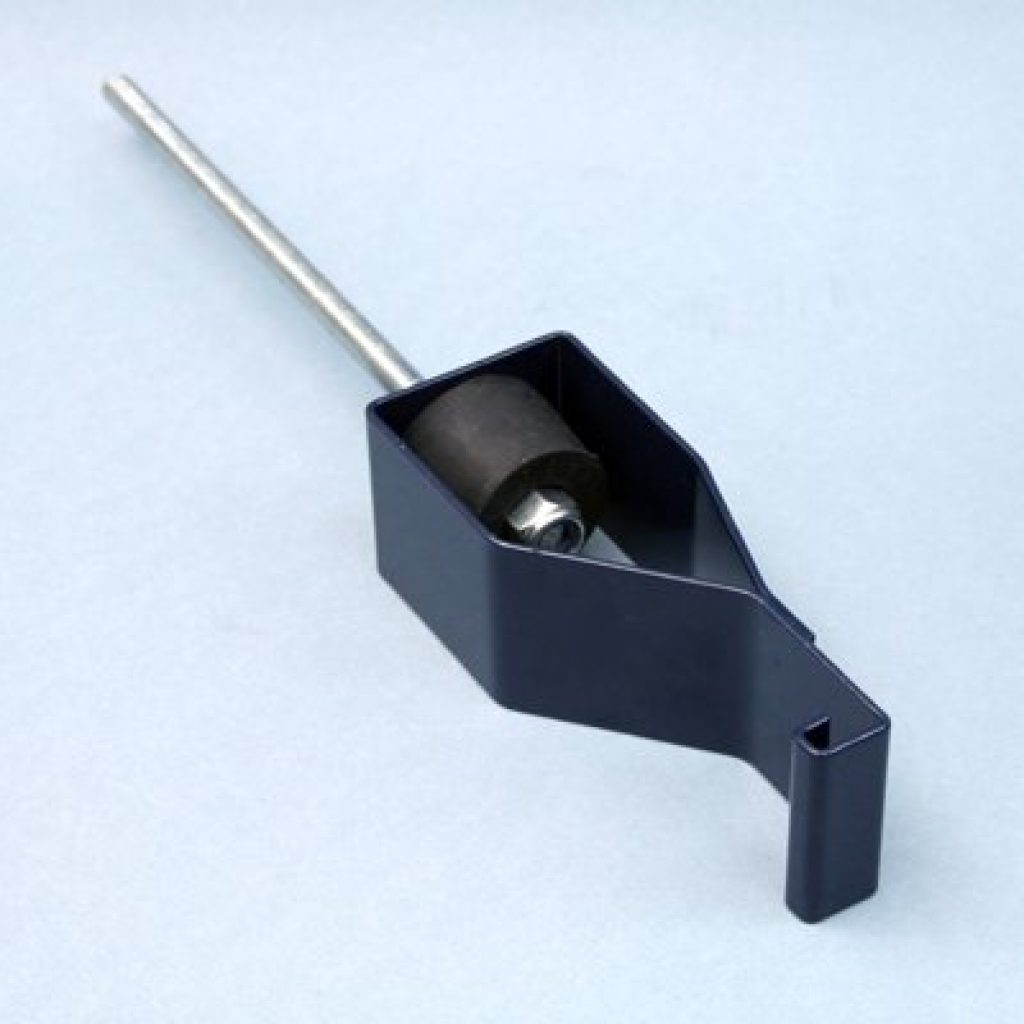

After the floors were jacked, Mason supplied a whole host of other acoustic products for the studios, including the NPS partition supports, AB-716 acoustic head restraint angles for the isolated walls and HDQF acoustic hangers for the isolated ceilings. Most of these products were held in stock in our warehouse and supplied shortly after orders were received.

The following video shows one of the floating floors being jacked to the desired height.