Acoustic solutions for Temple Quarter Enterprise Campus, Bristol University

A render of the Research Hub, Temple Quarter Enterprise Campus, Bristol University

Mason UK was awarded the contract by Aztech Building Services to provide a range of acoustic and anti-vibration solutions to the Temple Quarter Enterprise Campus project for the University of Bristol. Working with AHMM architects and Acoustic Consultants Max Fordham, Mason UK worked on the research hub, consisting of the renovation of an existing coal shed; a historic brick building dating back to 1885 that has been outfitted with a modern CLT timber structure within.

The project is described by the university as, “a flagship project for the University of Bristol and the city as a whole, designed to enhance the power and the potential for the creative, digital and innovation sectors to meet the needs of a rapidly changing world.”

With both the re-use of an existing structure and the adoption of CLT for the new internal structure, sustainability was a key consideration on this project; indeed the whole TQEC campus will be, “car free and the most sustainable part of our estate, helping to achieve our ambition to become carbon neutral by 2030.”

With both the re-use of an existing structure and the adoption of CLT for the new internal structure, sustainability was a key consideration on this project; indeed the whole TQEC campus will be, “car free and the most sustainable part of our estate, helping to achieve our ambition to become carbon neutral by 2030.”

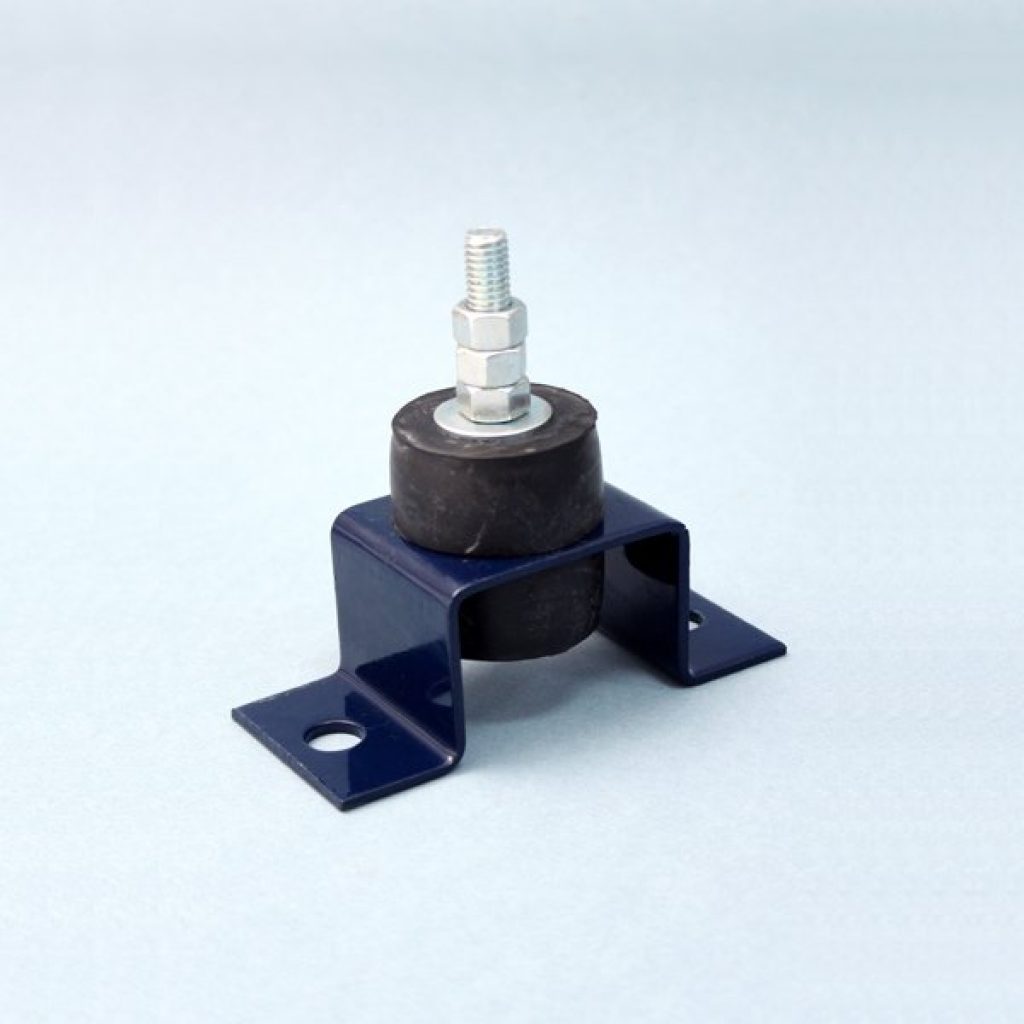

Mason UK provided a broad range of different solutions to match the specific requirements of the project; FSN concrete jack-up floating floors, rubber bearings for the parts of the CLT structure, spring ceiling hangers, acoustic sway braces and lightweight boarded floating floors.

One of the key compromises with any timber structure is acoustic performance; the lightweight nature of the structure will always present challenges in achieving the desired acoustic performance compared to a traditional concrete frame structure. With this in mind, key areas of the project were identified by the architect and acoustic consultant to receive an FSN concrete jack-up floating floor; the studio, instrumented auditorium, audio visual control rooms and CAR room. This project demonstrates how a more robust acoustic solution can be incorporated into a sustainable structure where necessary.

For the projector room and edit suites on the mezzanine level, lightweight EAFM floors were installed, consisting of two layers of boards supported on 50mm rubber mounts, all supplied and installed by Mason UK. This build-up is designed to provide adequate acoustic performance without the need for a concrete solution, all within a slimmer overall height.

One of the challenges of this installation was working around all the wiring and services, especially in the projector room. Thankfully, our experienced installers and project engineers were able to adapt the installation to suit without any compromise to the integrity or acoustic performance of the floor.

Mason UK additionally supplied isolation bearings for the CLT structure and spring ceiling hangers to the respective contractors on site. The bearings were custom made for this project and ranged in size from 125 x 125mm to 200 x 200mm, all at 100mm thickness. Mason UK can custom fabricate bearings to suit any loading conditions depending on the requirements of the project.

“It was great to be involved in this project from start to finish, throughout design, supply and construction phases across a whole range of stringent acoustic requirements,” explained Steve Hart, director at Mason UK.

“This type of project encompasses what Mason UK can offer with everything from the design and supply of Isolation Bearings supporting the CLT Structure, designing and installing Jack Up and Lightweight Floating Floors, supplying wall isolation sway braces and acoustic spring hangers for suspended ceilings.”