Structural Isolation for Sadler’s Wells East

The East Bank development

The East Bank development is an ambitious project that is part of the London 2012 legacy. This development includes a new site for Sadler’s Wells, the world-renowned dance theatre. Bringing the vision for the new building to life has involved significant engineering, including ensuring the building’s occupants won’t be disturbed by noise and vibration from freight trains passing nearby. To help overcome this, Mason UK designed and manufactured a system of bespoke bearings to isolate against sources of vibration.

The East Bank development, located on the east bank of the River Lea in Stratford, is part of the Queen Elizabeth Olympic Park. Once fully complete, it is estimated that the new cultural quarter will bring an additional 1.5 million visitors to the park every year, create more than 2,500 new jobs and generate an additional £1.5 billion for the local economy.

The East Bank is described as a ‘new powerhouse for innovation, creativity and learning’ and its name deliberately invites comparisons with South Bank. The development brings together universities and world-famous cultural institutions, including University College London, UAL’s London College of Fashion, the BBC, Sadler’s Wells and Q&A.

Sadler’s Wells is a globally renowned dance company with three centuries of theatrical heritage. Sadler’s Wells Theatre is located in Clerkenwell, and the site has been continuously occupied since the time of the Restoration in the late 1600s. The East Bank will be home to Sadler’s Wells East, an entirely new site, offering a 550-seat dance theatre, a new choreographic school, and a hip hop theatre academy.

The building was designed and created by architects O’Donnell and Tuomey, and dance practitioners were consulted in the early phase of the design process to ensure the finished building caters to their needs. However, for the building to function as intended, sophisticated acoustic engineering was required. Having consulted with specialist acoustic consultant Charcoal Blue and structural engineer Buro Happold, the contractor Kilnbridge turned to Mason UK for our expertise in vibration control.

The major challenge facing the contractor was the proximity of the site to a major trainline, including the Elizabeth Line which opened in May 2022. With freight trucks passing right across the front of the site, there would be plenty of low frequency vibration generated. Without the correct isolation methods in place, this vibration would manifest as low frequency noise in the dance studios. Mason UK was tasked with resolving this problem.

Mason UK was working on several studios that required acoustic isolation, but the biggest challenge came from Studio One. While all the studios in the facility are large, Studio One, which sits adjacent to them, is a large venue constructed on a steel frame. This involved the installation of five main trusses, spanning approximately 25 meters and weighing around 20 tonnes each.

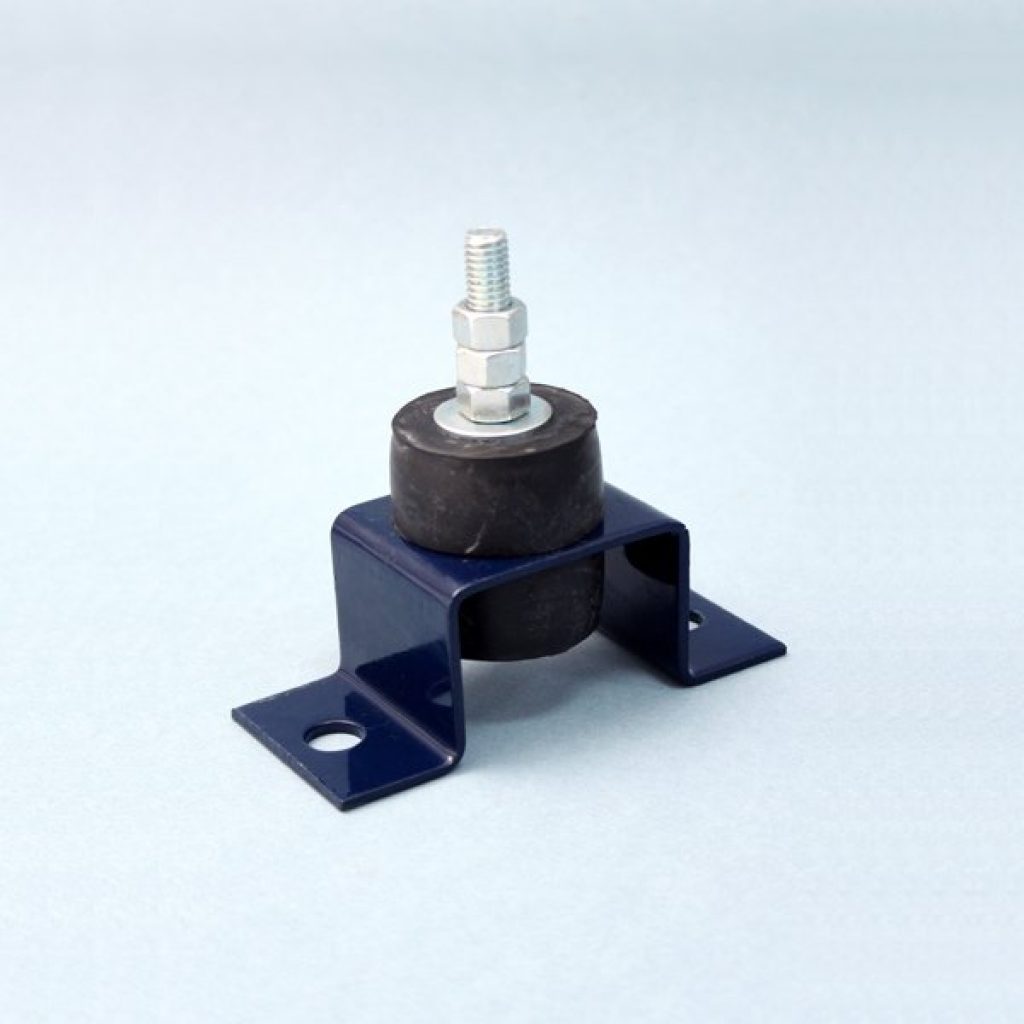

To isolate effectively against the vibration emanating from the trainline, a bespoke solution was required. Acoustic floating floors are often the most effective solution for isolating dance studios. Indeed, Mason installed several floating floors for Kilnbridge, the contractor for Sadler’s Wells East. However, due to the vast size of Studio One, large rubber bearings were a better option, and these would be used to isolate the vast steel trusses from the concrete structure.

With an area this size, it made more sense to position point loads of large bearings spread out around the perimeter. In total, eleven support locations were required to support the trusses at intersections. Having lots of isolators spread out over a floor this size, as would be the case with a floating floor, would be less cost effective and the use of large bearings also had the benefit of keeping contact points to a minimum so offered superior acoustic performance.

Rubber bearings can be designed to provide low natural frequencies, as low as four to five Hertz if necessary. The low dynamic stiffness of Mason proprietary rubber formula makes it a highly effective material choice for an isolator, even for the low frequency vibrations that would be generated by freight trains. The kind of bearings used for Sadler’s Wells East were the type usually used when isolating entire buildings. Furthermore, as this is not an off-the-shelf product, each bearing had to be specifically designed to handle the loads it will face.

Mason had to work closely with the structural engineer to achieve this engineering feat. It was necessary to determine the load that each bearing would be subjected to. From the perspective of the structural engineer, it makes sense to factor up loads for reasons of safety, but if you were to design a bearing on the basis of a load requirement that is much higher than what will be experienced, it will not compress enough and therefore fail to deliver the right acoustic performance.

In addition to designing bearings that would respond in the right way to the true loads they would be subject to, it was also necessary to take into consideration how they would work around the existing building structure. For instance, in some places there would not be sufficient width of wall to accommodate a large bearing, so two or three smaller ones had to be used instead. Being able to adapt to different space envelopes was another advantage of having bespoke bearings.

Although the bearings provide the ideal acoustic solution, they also introduced a further engineering challenge — handling lateral forces. Structural engineers need to ensure the building is designed to withstand the impact of lateral forces, such as wind loads from hurricanes or even terrorist activity. In the case of Sadler’s Wells, significant collapse forces had to be supported.

Mason UK therefore had to design a system of bespoke shear keys to accompany the bearings. Because the forces were so large, Mason UK proposed separating into ‘working’ day to day forces to be handled with acoustic bearings placed laterally, and ‘emergency’ load conditions for which large steel bump stops were incorporated. This approach greatly reduced the cost and prevented the need for bearings which for day to day forces would be far too stiff.

Acoustic bearings were also used to isolate the entire plant area on roof level – unique steel to steel connections were developed as a simple way to reduce uncertainty of noise and vibration generated by air handling and water heating systems.

Although the work on Studio One was the most challenging, it was far from being Mason’s only contribution to this building. In total, seven concrete sprung floating floors were designed and supplied for different studios spread across two levels. Floating floors provide a gap or clearance between the floor and the underlying structure, providing isolation against vibration from the trainline as well as the transfer of airborne noise from adjacent studios.

Concrete floating floors can be supported on elastomeric elements or springs. The latter have far less internal damping than rubber so can absorb more vibration. For Sadler’s Wells East, Mason supplied one of its highest performing floating floors, the Mason FS Sprung Floating Floor.

The jack up floating floor, pioneered by Mason Industries in the 1960s, remains the most effective construction method for installing a floating floor. This uses the Mason jack-up system to raise a concrete layer using adjustable jacks. More specifically, helical springs provide support to the concrete floor, absorbing any positive sources of vibration. The system offers a high level of flexibility and guarantees an air gap.

Once completed, Sadler’s Wells East will stand out as among the world’s most innovative dance studios and a shining example of the London 2012 legacy. All of those involved in the project have shared a sense of pride in helping deliver on this ambitious vision.

‘‘It always exciting to be involved in projects of this scale and the unique challenges they present,’’ recalled George Taylor, a senior project engineer with Mason UK. Marius Butnaru, a site engineer with contractor Kilnbridge, was equally excited about his involvement in this project. ‘‘These are highly specialised structures, so it is a privilege to be involved in a project like this.’’

Discussing the unique challenges of this project, George explained that ‘‘most companies can only offer off-the-shelf projects, but it was clear that for these large steel trusses, we needed to design a bespoke solution, including specially designed sheer keys. This was similar to structural work, so we had to work closely with the structural engineer to get the design perfect, both from a structural point of view, but also from an acoustics points of view.’’

Reflecting on the collaboration between Mason UK and Kilnbridge, Marius was equally positive. ‘‘We have had a very good relationship with George, Adam, and the Mason team throughout this project. George has been on-site regularly, providing guidance on how to utilise the bearings and carrying out inspections. If there are any problems with a bearing being slightly out of position for example, he will spot it. This is highly specialised equipment, so you need that expertise.’’

Providing acoustic isolation was a unique challenge given the proximity of the Elizabeth Line and the vast scale of the Studio One. In this area of engineering, Mason UK has a reputation for providing solutions where others are unable to do so. In the words of Adam Fox, director of Mason UK and someone who worked closely with the structural engineers involved in the design of Sadler’s Wells, ‘‘there are very few companies out there that can do this kind of work, so this is a real opportunity to showcase what we can do and be part of an ambitious development.’’