Building Services (HVAC) Vibration Isolation

Mason UK are greatly experienced in isolating building services (HVAC) and equipment to reduce vibration transmission. We can support the design of plant isolation systems, starting from the source of vibration, through to associated services and structural connections. Often a range of piping and ductwork services shall need the same level of isolation of the source and the requirement can extend throughout the building.

Several factors need to be considered:

- What are the project requirements – is there a mechanical or acoustic specification?

- Is the source of vibration (a booster pump for example) on anti-vibration mounts? Flexible connectors should be considered to prevent pipe failure and allow movement.

- Temperature change – are the pipes likely to expand and contract with varying temperatures? Expansion compensators and/or pipe guides may be required to allow for this movement.

- Is adjoining pipework fixed to the floor, walls or ceiling? A combination of Isolation hangers and floor mounted isolators (spring & rubber) will uphold the vibration isolation at the source and allow a small amount of movement and expansion.

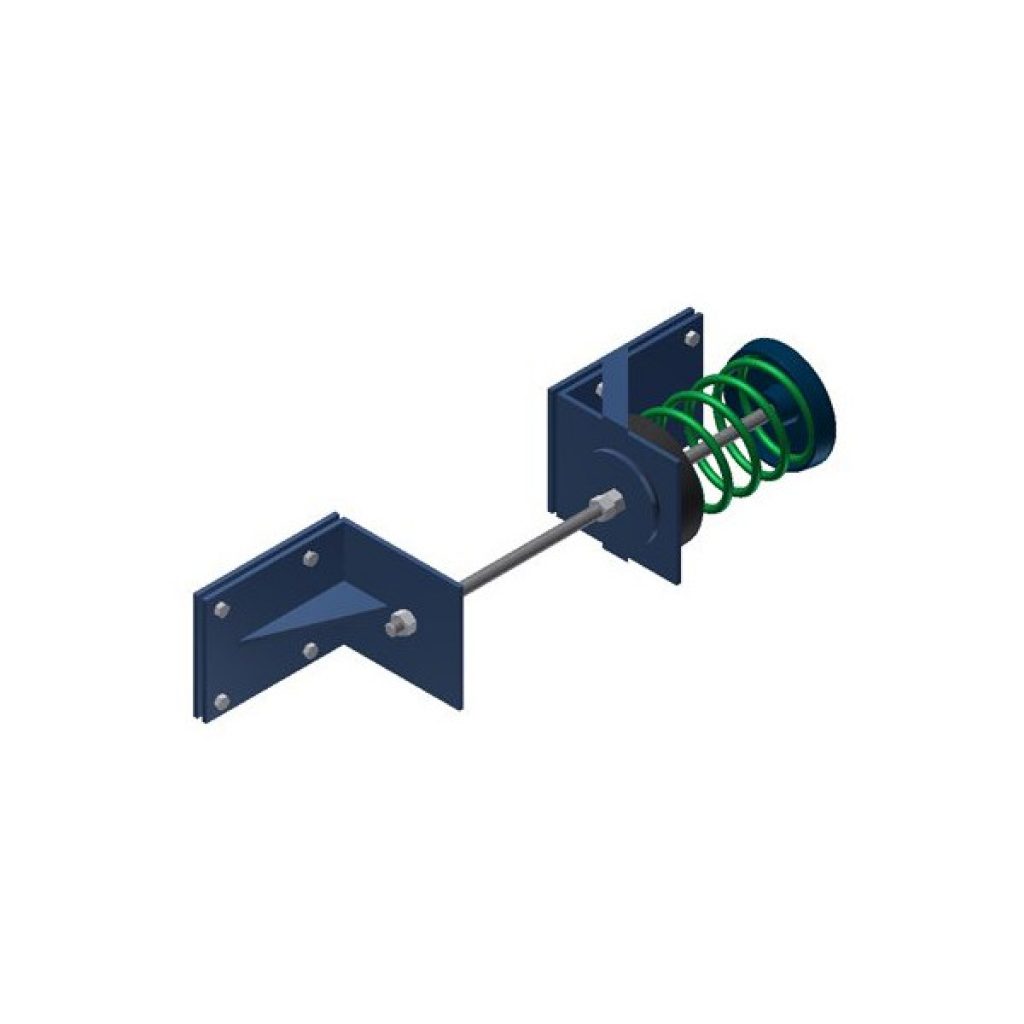

Mason UK is equipped to assist with the design, selection and specification of isolators, taking the above points into account. We can also provide calculations, installation drawings and provide site support. See the below image of a SKID in BIM format (Building Information Modelling) that Mason produced for a prestigious pipe system isolation project.

SKID of a complex pipe isolation system designed and produced by our engineers in BIM format.

We are able to supply the following:

- 3D drawings for BIM compliance.

- Flexible connectors for thermal expansion and movement allowances.

- Array of connectors to suit a wide range of chemical, temperature and pressure requirements.

- Vee connectors for seismic and large deflection applications.

- Bespoke designs to meet requirements.

- Control rods and cables for tied requirements.

- Pipe isolation systems incorporating anti-vibration hangers, mounts and more.

- Piping guides to allow movement for horizontal and riser systems.

- Expansion compensators to allow for temperature variation.

The above list outlines ways in which we can help on your project, but it is not exhaustive. If you have any building services (HVAC) vibration isolation requirements, please contact our experienced team of engineers.

| Specification Documents |

|---|

If both the deflection of the structure and nature of the equipment is known, the following specification documents can help when generating a vibration isolation specification for HVAC applications. Our engineers are on hand to assist and give advice as necessary.

Related Products

Please see the following product pages to find out how we can help with your project: