Concrete Floating Floors for Peloton Headquarters, Covent Garden, London

Floral Street, Covent Garden

Mason UK were awarded the contract to Design, Supply, and Install Concrete Jack Up Floating Floors for the brand-new Peloton headquarters in Covent Garden. In addition to being a prestigious project for an innovative, high-end fitness brand, the historic setting of Floral Street (just one street over from Covent Garden Piazza itself) presented a host of logistical challenges to overcome, including close proximity to the general public in one of the most popular tourist destinations in London, as well as the need for impeccable cleanliness to preserve the surrounding area.

Mason UK worked directly for the principal contractor Knight Harwood, with the acoustic consultant for the project being Longman Lindsey, a prestigious consultant based in New York City.

The project consisted of building a box-in-box construction for the three studios and a plant room on three different levels within the building. For the Spin and Tread studios on the ground floor, the limited weight capacity of the existing structure combined with the need for high performance 150mm concrete floating floors with a sub 4Hz natural frequency, meant that an unusually large number of jacks on much tighter centres than usual were required. At certain locations, additional steel spreader plates were needed where jacks could not be located directly onto steel filler beams within the structural slab further complicating the design.

For the Flex studio on level 1, the floor was constructed on a new steel frame, which required careful coordination at both the design and construction stages to ensure the steel beams lined up perfectly with the jack locations. On all the floors, a large number of recessed boxes were cast into the floor to accept electrical floor boxes later on. Mason UK worked in close collaboration with the site engineer to ensure accurate setting out of each box, which all had to be in very specific locations to accommodate the equipment layout.

Above – Note the floor poured on a plywood form with steel load bearing plates at each jack location.

Because of the nature of the location and the main contractor’s agreement with the local council, all deliveries and works outside the building had to be completed and the road re-opened by 13:00. Careful attention had to be paid to traffic and pedestrian management due to the one-way system of Floral street and most of the surrounding streets. Working within these constraints and in close collaboration with the main contractor and their logistics team, our experienced team were able to complete all our deliveries and concrete pours on time every time.

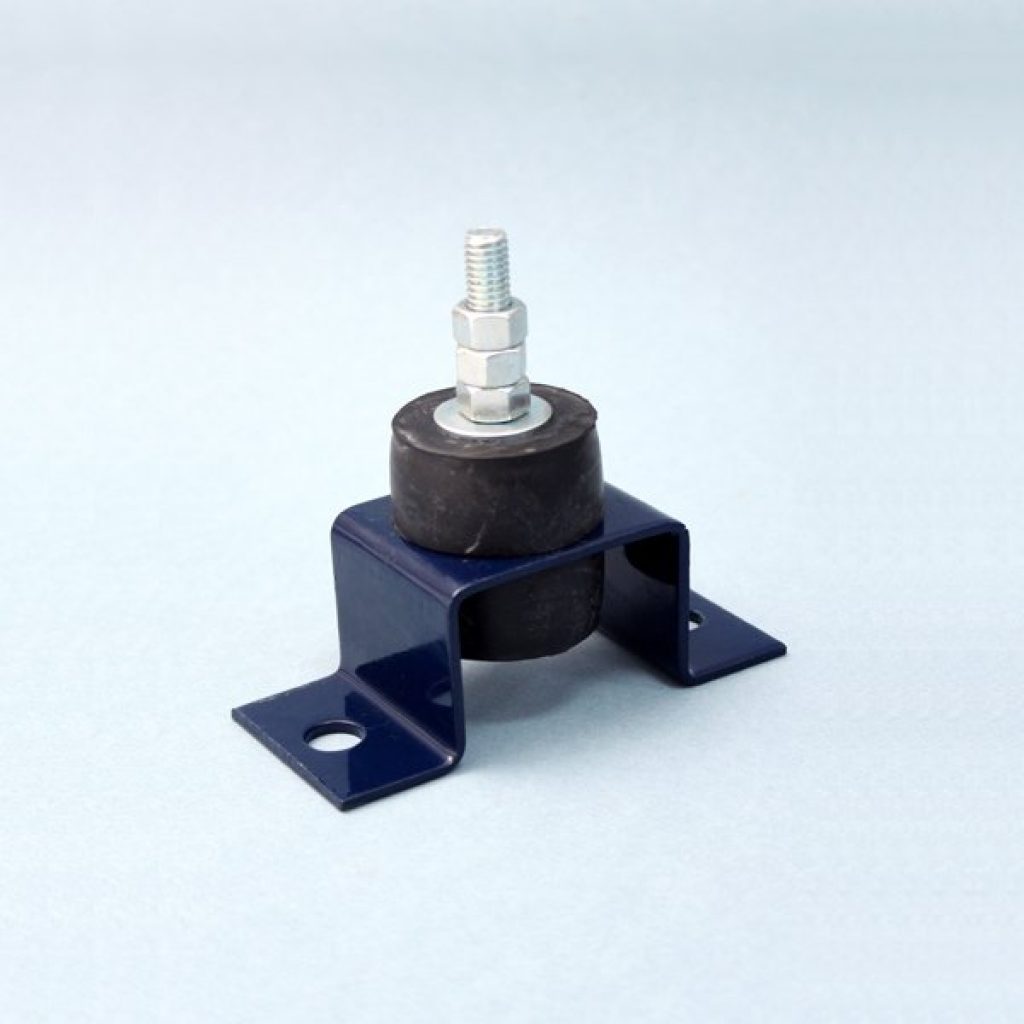

Mason UK were also separately contracted by Roskel Contracts to provide spring hangers and sway braces for the ceilings and walls respectively of each studio and the plant room to complete the box in box constructions. Due to the complex M&E arrangement in the ceiling void, as well as numerous structural steel beams, the hanger layout for each studio had to be carefully considered and we were able to provide fully dimensioned layout drawings. Multiple spring stiffnesses were needed to provide consistent acoustic properties across each ceiling.

Even with careful coordination, practical considerations meant that there were a small number of conflicts on site. Once notified of the issues, Mason UK were quick to send an engineer to site to assist, and provide a resolution ensuring progress on the project was not delayed.

At Mason UK, we are not afraid of challenging, high-status projects! If we can assist with your project, please do not hesitate to get in touch and speak to one of our friendly and knowledgeable engineers.

See below for further construction photos.