Air Sprung Inertia Base for Laboratory Equipment – Oxsonics, Oxford

Oxsonics carry out pioneering cancer research. Vibrations disturbance caused by nearby construction work was preventing them using some sensitive ultrasonic equipment. This operated at very high levels of precision and so the vibration severely affected their experiments. Following assessment by Hoare Lea Vibration, we designed and installed a steel base supported by Mason MT Air Springs.

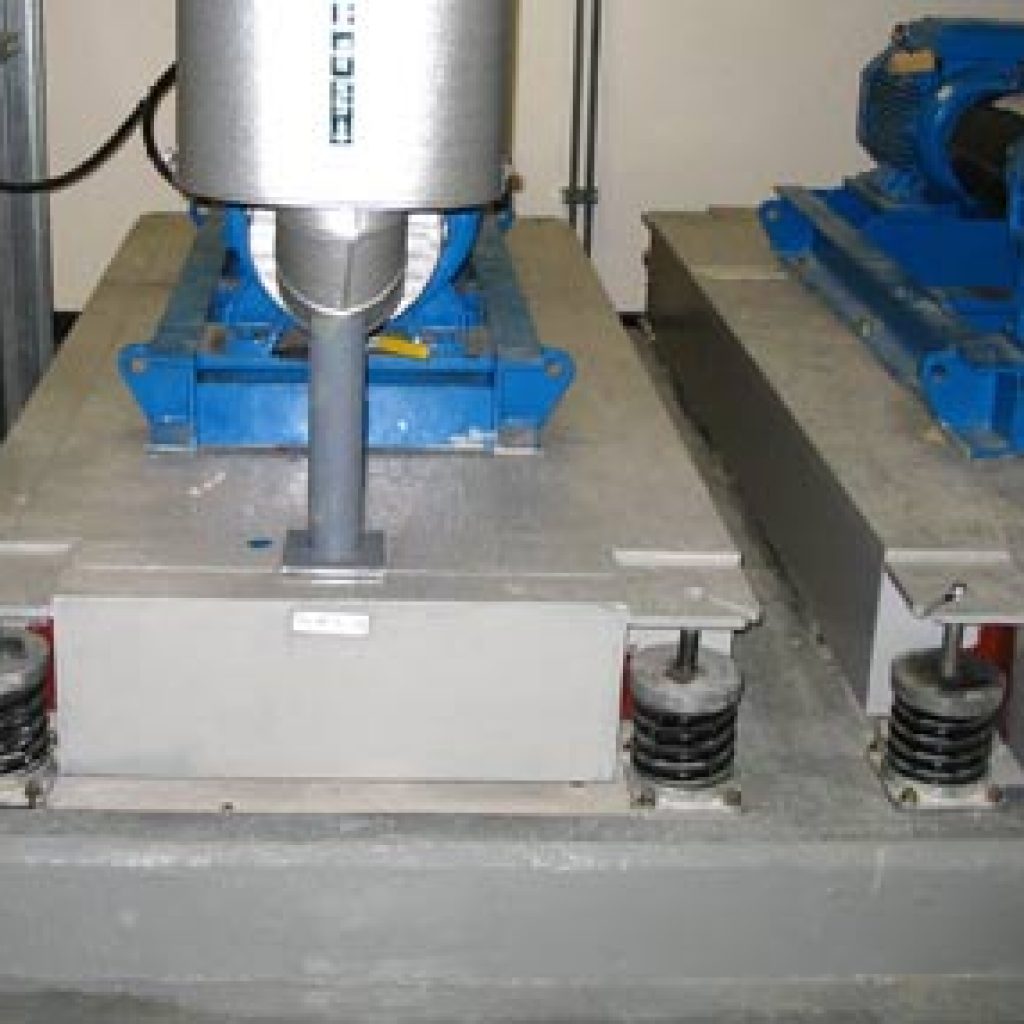

The base was located in the centre of a test facility, so it was important to reduce disruption to a minimum. We designed a steel base made of parts which could be easily transported and assembled cleanly, a build-up of six 25mm steel plates to add mass rather than use concrete as would be typical. The bespoke base was designed to fit the legs of the equipment precisely and fit within the existing raised access floor. Part of the ultrasonic equipment was a water tank so consideration of stability was part of our design.

The three black canisters are used to increase the system air volume, which in turn decreased the natural frequency and allowed damping to be adjusted via needle valves, ensuring optimum vibration isolation. We could not use vertical air columns due to space restrictions. The hoses leading to the tanks had to be a given length, hence are coiled and tied.

The air springs are positioned on each corner and were selected with a capacity that suits the overall system once everything is in place. The system itself will operate at the set height throughout and uses a venting and compressed gas system (Nitrogen) to regulate. Mason U.K. supplied everything including the air tanks and regulator.

The air sprung base is set to a level using valves with turnbuckles and once set, the base will automatically adjust itself whenever any changes occur to the system or equipment weight, ensuring it is level and has the correct height at all times.

The control panel was supplied with a set of written instruction for the system, which is helpful if any maintenance or changes occur. Any change in system mass could lead to wasted gas, so in order to minimise this there is a sequence of valves employed to stop continuous flow. All required information including step by step processes for this can be found on instructions provided and Mason U.K. will provide support for the lifetime of the installation.

Mason UK carried out the full installation of the air sprung base, working with the client and maintenance company on site in order to ensure ease of completion. The system is maintenance free and can be made to suit a vast variety of sizes and environments.

This project is a prime example of how we are able to solve all manner of vibration issues, and work with great efficiency and flexibility. Further information on vibration isolation for science and medical facilities can be found here.

If you would like us to assist with a vibration isolation project, or would like to learn more about our products, please contact one of our friendly engineers.

See below for further construction photos.