Mechanical Vibration Isolation

Mason UK are able to assist with many aspects of mechanical vibration isolation including the design, selection and installation of anti-vibration mounts, to 3D modelling to support BIM and carrying out clash analysis to ensure a painless installation.

We can facilitate the anti-vibration isolation of a wide variety of mechanical equipment such as Air Handling Units (AHUs), Pump Sets, Extract Fans, Pipework, Ducting, HVAC and more. Below are a few different ways in which Mason UK are able to help you on your project.

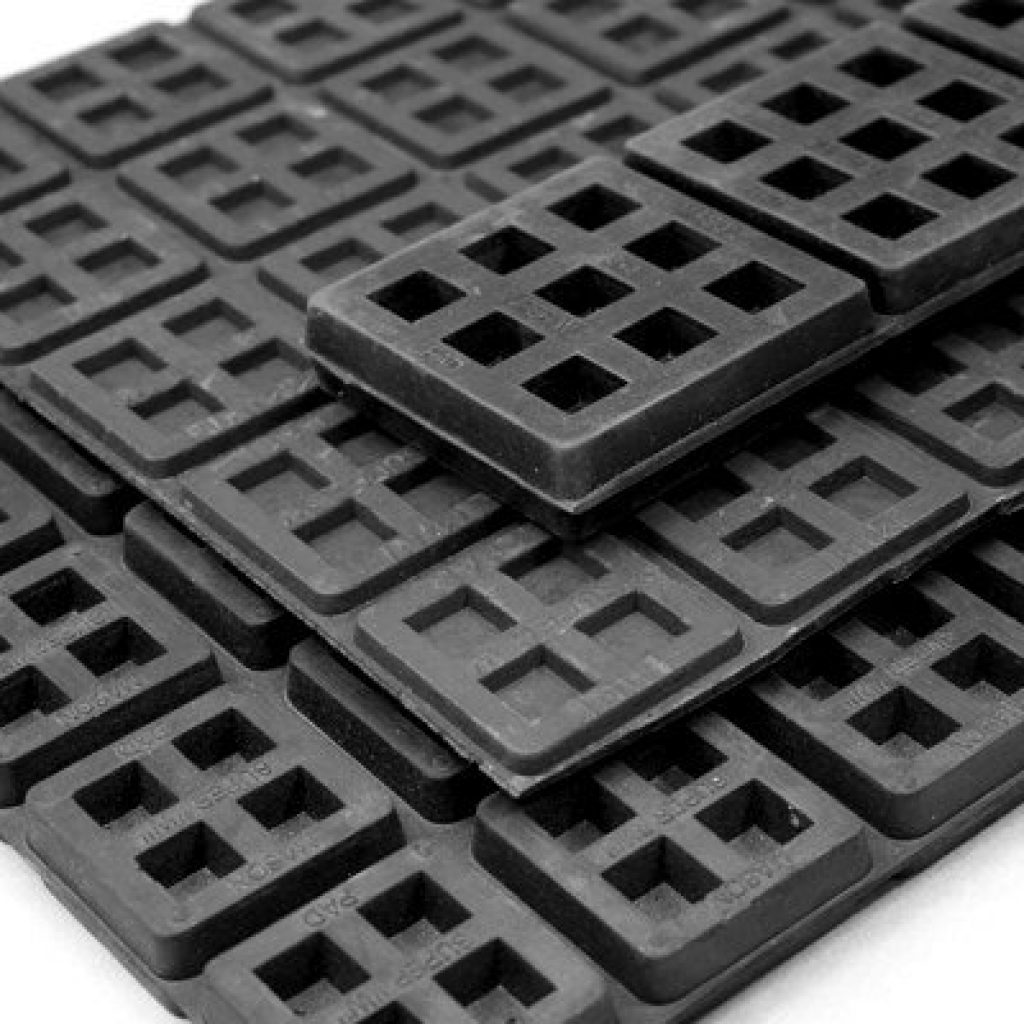

Selection and supply of anti-vibration products

Our highly knowledgeable engineers are able to carry out calculations of anti-vibration (AV) product location loads, select appropriate products for the application and ensure compliance with an acoustic specification. Isolators can incorporate either metal coil spring, Low Dynamic Stiffness (LDS) natural rubber elements, or a combination of the two. We can generate anti-vibration schedules and work with the contractor to reach the most economical solution, whilst considering the available space and installation restrictions.

Designed to meet performance specifications

Where mechanical equipment is to be installed on a project, and there is a potential for vibration/noise disturbances, it is common for an anti-vibration performance target to be specified by and acoustic consultant. Examples are a vibration isolation efficiency target in percent, the natural frequency of the isolators products in Hz, or a minimum deflection value in millimetres. Regardless, we can take responsibility for meeting the project specification.

We have a great deal of experience in calculating the predicted isolation efficiency, natural frequency and or deflection of our products under load. The target values will dictate whether spring, elastomeric or a combination of the two is required. We are happy to work with you to propose the most effective and cost saving solution.

The following graph shows how the relationship between the natural frequency of the isolator and the vibration source affects the level of isolation. If the incorrect selection is made, amplification can result which will make the problem worse. This graph does not take into account isolator damping, the supporting structure, the system stability or situations with multiple vibration sources which can significantly affect the outcome – we consider all aspects before recommending a solution.

Supply and installation

As well as supplying our products, we are able to offer supervision on site or a complete installation service. Our products are straightforward to install and we provide installation guides, but experience is useful for ensuring correct installation. We are happy to assist. In some cases, it is necessary for isolators to be installed after the equipment is in place and commissioned. This is known as the practice of retrofitting. This practice is typically required when it becomes apparent that the vibration of existing equipment is causing a disturbance. We are able to attend site and review the installation, before generating a proposal. Bespoke solutions can be designed to integrate seamlessly with the existing installation such as custom-made brackets, modified products and designing complete support structures.

See below for a few examples of successful solutions here:

We are able to carry out the placing and setting of our products to provide a “turn-key” package. We work closely with the contractor and or client on site to ensure a smooth installation. If you would like us to attend site to discuss potential solutions and give advice, please contact our team who will be happy to help.

Building Information Modelling (BIM)

It is becoming more common that projects will incorporate a full 3D model of the services within an entire building or specific locations, in the form of Building Information Models (BIMs). This is a digital representation of the physical and functional characteristics of a facility which would include all services and equipment. We are able to insert our product selections into the 3D BIM, which allows for the review of available space and utilisation of “Clash Control” to ensure that all of our proposed products will fit in place and can be installed with ease. We can also produce 3D BIM Skids to allow the contractor to pre-manufacture the assemblies if beneficial. We can also carry out pipe stress and thermal expansion calculations, which can affect the selection or isolators, guides and anchorage, plus the need for flexible connections. This can apply to risers and industrial services.

The above outlines only a few ways in which Mason UK can help on your project. If you have a requirement for vibration isolation of any type, please contact our friendly team of engineers.