Search Results:

Your Search Filters:

Equipment Category: Refrigeration Machines

Equipment Type: Centrifugal Chiller

Equipment Details: Open Drive Type Compressors

Floor Slab Span: 30 ‘(9m)

Plant Isolation Details

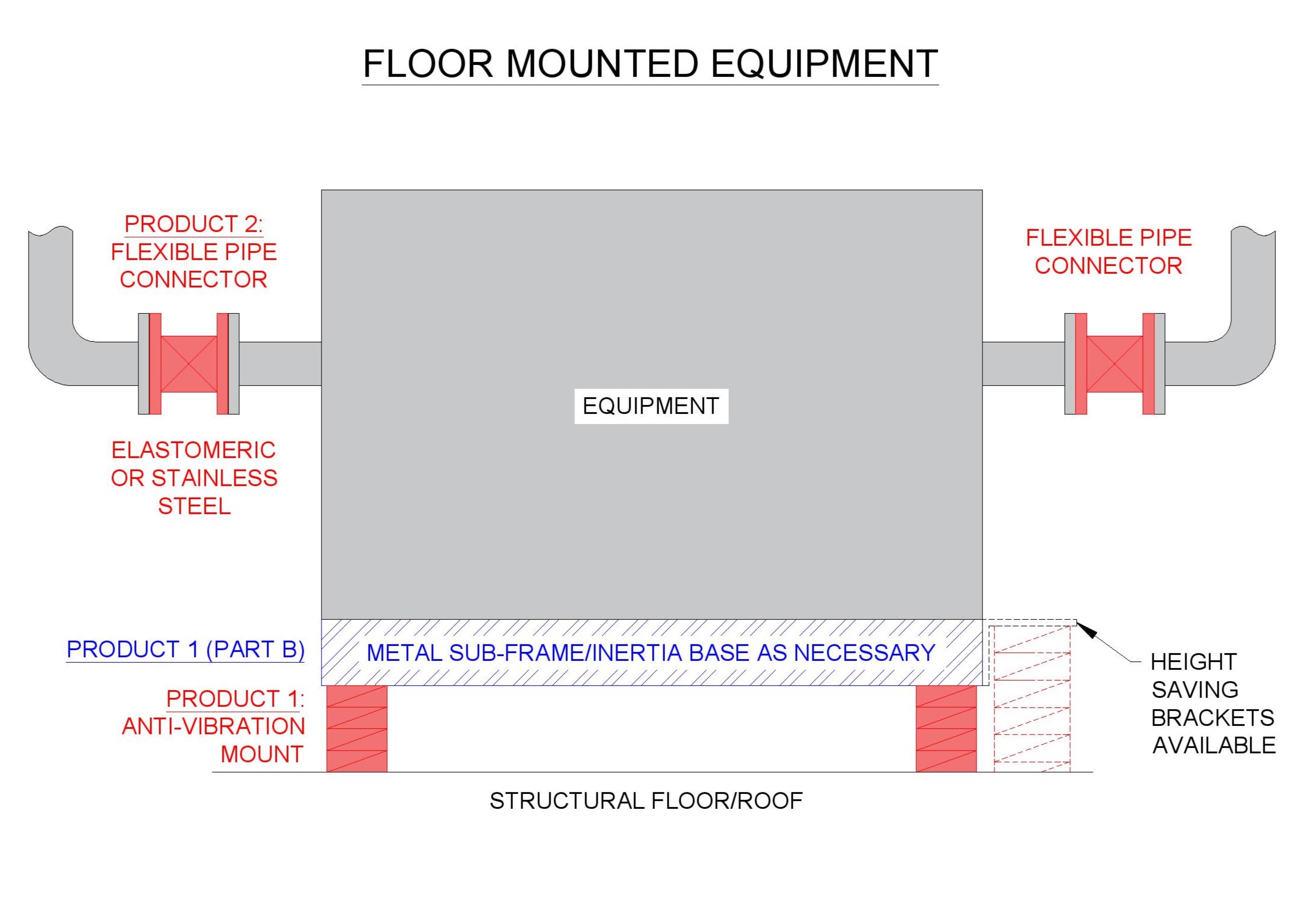

To meet CIBSE vibration isolation guidelines, your equipment must be isolated using Product 1: Restrained Spring Mounts, Product 2: Safe Flex Pipe Connectors, Product 3: Control Rods and Cables as a minimum. These must have the correct properties specific to your installation, provided in the specification text for each product type below. Click the following links to download the CIBSE compliant specification text or simply click here to request Mason UK contact you about your installation.

Specification

Product:

Anti-vibration mounting to be type SLR (Restrained Spring Mounts) or SLRSO (Restrained Seismic Open Spring Mounts), as manufactured by Mason UK Ltd.

Performance:

Mounting must have a minimum static deflection/compression of [VARIABLE DEFLECTION] under the operating load.

Geometry:

The ratio of the Spring diameter by the compressed spring height cannot be less than 0.8. Springs to have a minimum additional overload capacity of 50% of the rated deflection/compression before becoming solid.

Housing:

Spring coil to be restrained in housing and colour coded. Mount to include a 6 mm neoprene acoustical friction pad between the base plate and the support.

Installation:

All mountings need to have levelling bolts that must be rigidly bolted to the equipment or metal frame. When installed, all operating heights must be equal.

For this specification we recommend the following product(s). Please follow the link(s) to view additional information on the Mason UK website.

- Copy specification to your clipboard (may not copy in all browsers)

Gallery

Case Study Images

Specification

Product:

Anti-vibration mounting to be type SLR (Restrained Spring Mounts) or SLRSO (Restrained Seismic Open Spring Mounts), as manufactured by Mason UK Ltd.

Performance:

Mounting must have a minimum static deflection/compression of [VARIABLE DEFLECTION] under the operating load.

Geometry:

The ratio of the Spring diameter by the compressed spring height cannot be less than 0.8. Springs to have a minimum additional overload capacity of 50% of the rated deflection/compression before becoming solid.

Housing:

Spring coil to be restrained in housing and colour coded. Mount to include a 6 mm neoprene acoustical friction pad between the base plate and the support.

Installation:

All mountings need to have levelling bolts that must be rigidly bolted to the equipment or metal frame. When installed, all operating heights must be equal.

For this specification we recommend the following product(s). Please follow the link(s) to view additional information on the Mason UK website.

- Copy specification to your clipboard (may not copy in all browsers)

Gallery

Case Study Images

Specification

Product:

Anti-vibration mounting to be type SLR (Restrained Spring Mounts) or SLRSO (Restrained Seismic Open Spring Mounts), as manufactured by Mason UK Ltd.

Performance:

Mounting must have a minimum static deflection/compression of [VARIABLE DEFLECTION] under the operating load.

Geometry:

The ratio of the Spring diameter by the compressed spring height cannot be less than 0.8. Springs to have a minimum additional overload capacity of 50% of the rated deflection/compression before becoming solid.

Housing:

Spring coil to be restrained in housing and colour coded. Mount to include a 6 mm neoprene acoustical friction pad between the base plate and the support.

Installation:

All mountings need to have levelling bolts that must be rigidly bolted to the equipment or metal frame. When installed, all operating heights must be equal.

For this specification we recommend the following product(s). Please follow the link(s) to view additional information on the Mason UK website.

- Copy specification to your clipboard (may not copy in all browsers)