Floating Floor Vibration Isolation of Gym, Kings Cross

Mason were specified to provide floating floors on this project in Kings Cross by Sandy Brown Associates. Floors were required in the Spinning Room, Cardio Suite, Strength Studio and Movement Studio comprising of over 900 square metres of flooring.

Mason UK designed and supervised the installation of the jack up floating floors, which utilised the FS helical spring jacks. The installation was quite complex, as the floor needed to fill a 300mm zone, but the structure could only accept an extra 100mm thick floor from lightweight concrete.

To achieve this, jack locations were supported on dense concrete blocks to take the point loads. The blocks were bedded on a full mortar bed and laid to a laser level. Between the blocks, dense mineral wool was used as an infill material to support the weight of the wet concrete. This also enabled the services for the cardio machines to be run in the insulation zone.

The largest floor was approximately 500 square metres and was poured in a single operation, and jacked in two days after the concrete had cured.

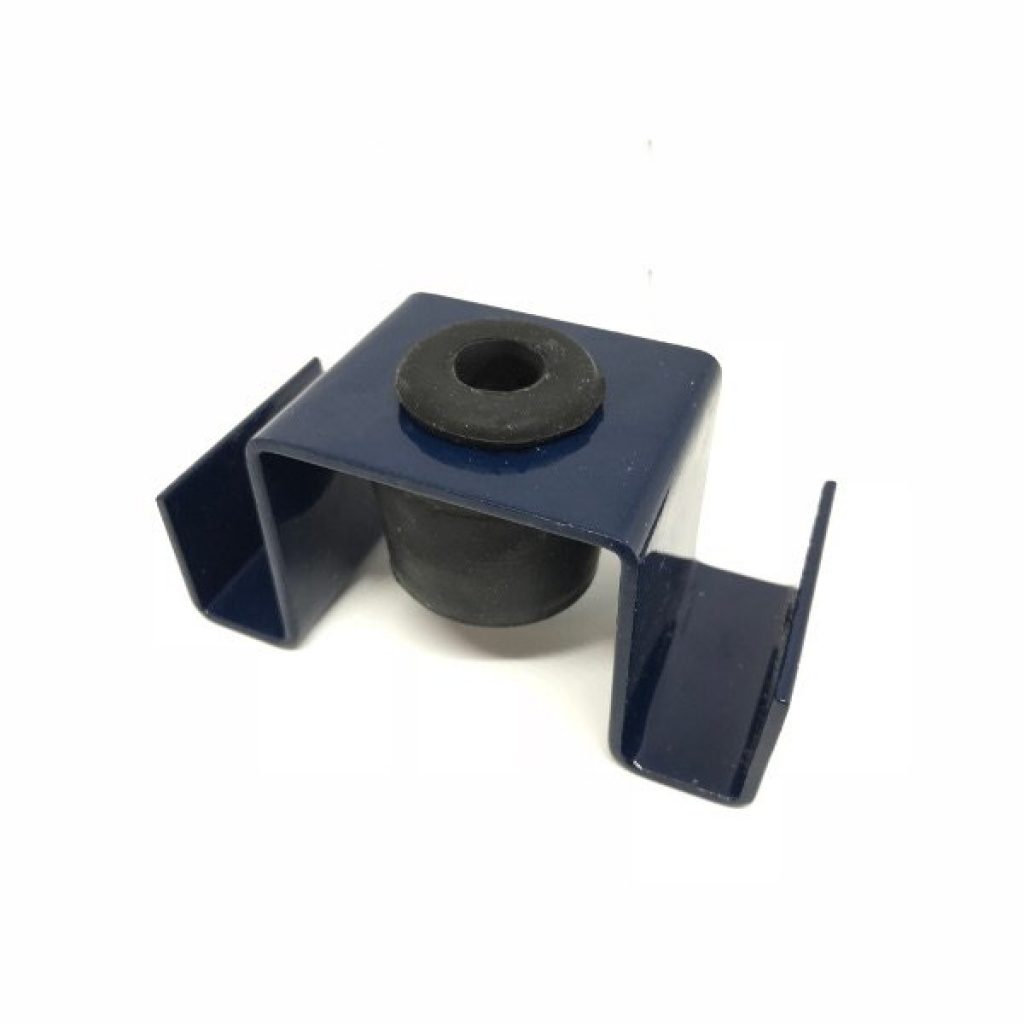

Mason UK also supplied acoustic hangers to support the services such as sprinkler and water pipes as well as hangers for the ceilings on this project to the relevant M&E and Dry Lining Contractors on site.