Dry and Formwork Acoustic Floor Systems

When designing a floating floor system, there are many factors which decide the optimum design. The best performing systems are typically heavy and thick, using a concrete layer, such as those described in the jack up floating floors. However, sometimes this is undesirable, or not possible due to structural and building limitations.

If the existing floor lacks sufficient strength, it is not desirable to pour concrete, or costs need to be controlled, a lightweight floating floor is often the best choice. Very high levels of noise and vibration isolation can be achieved with a correctly designed system.

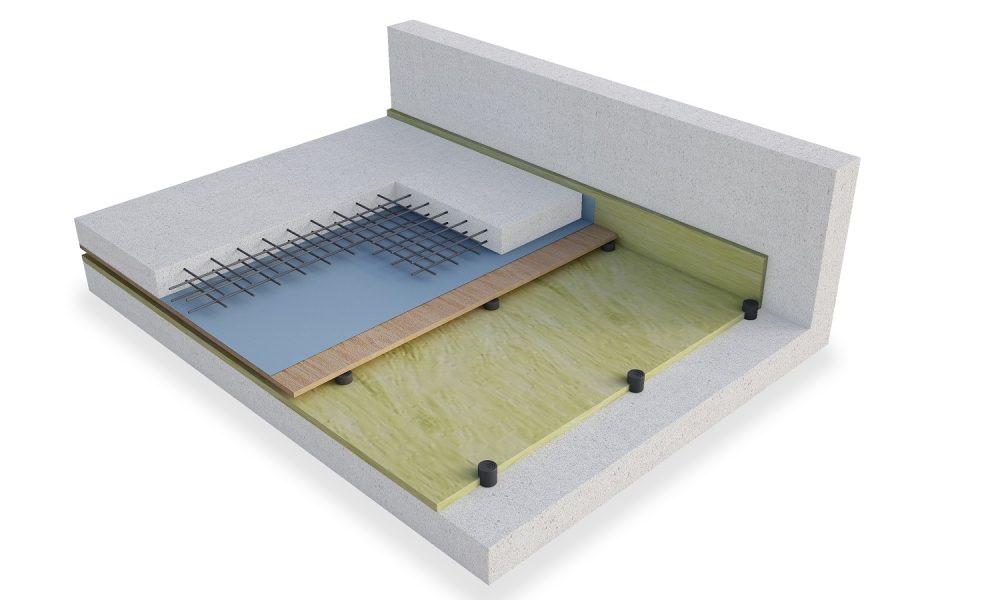

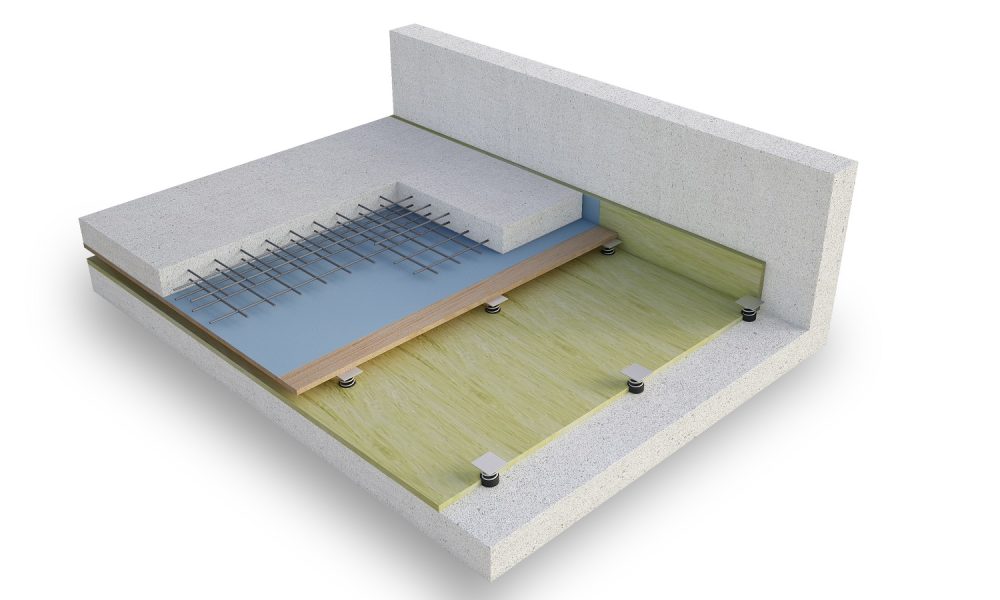

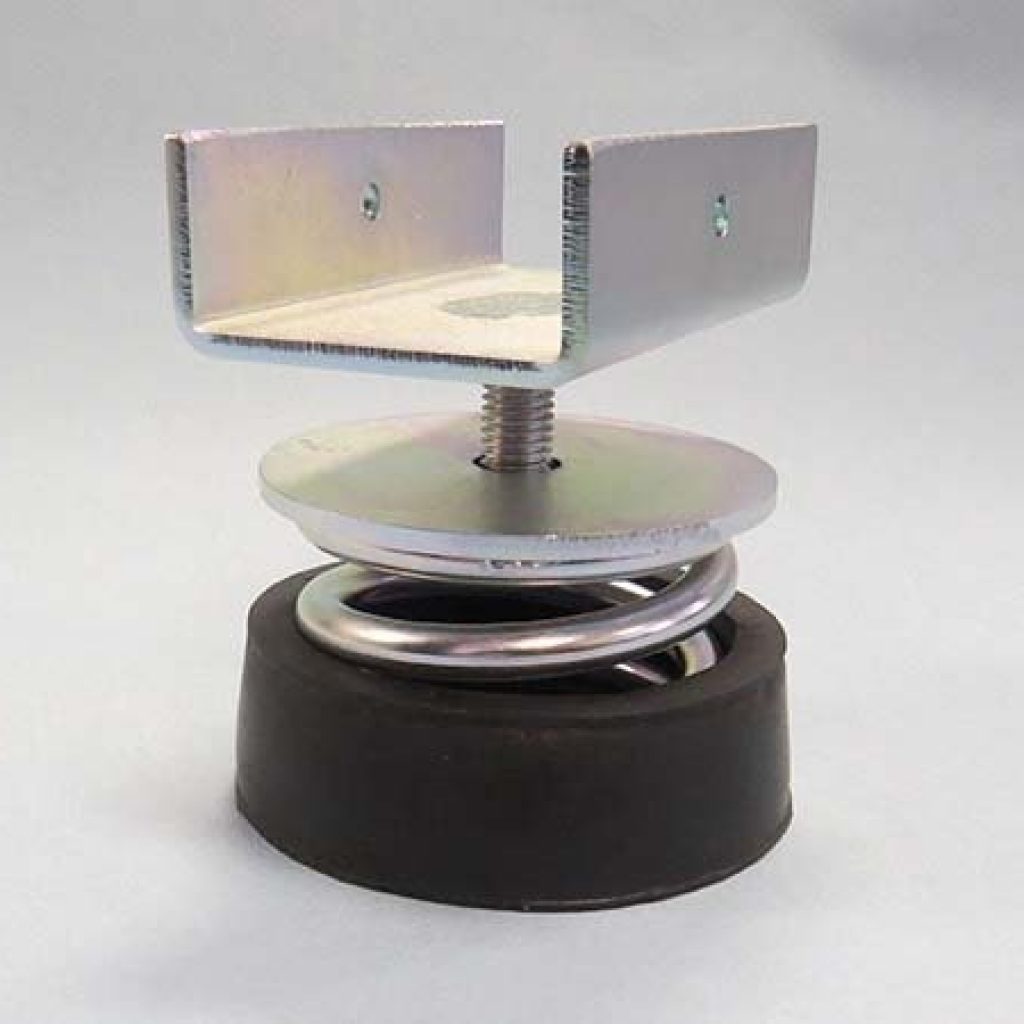

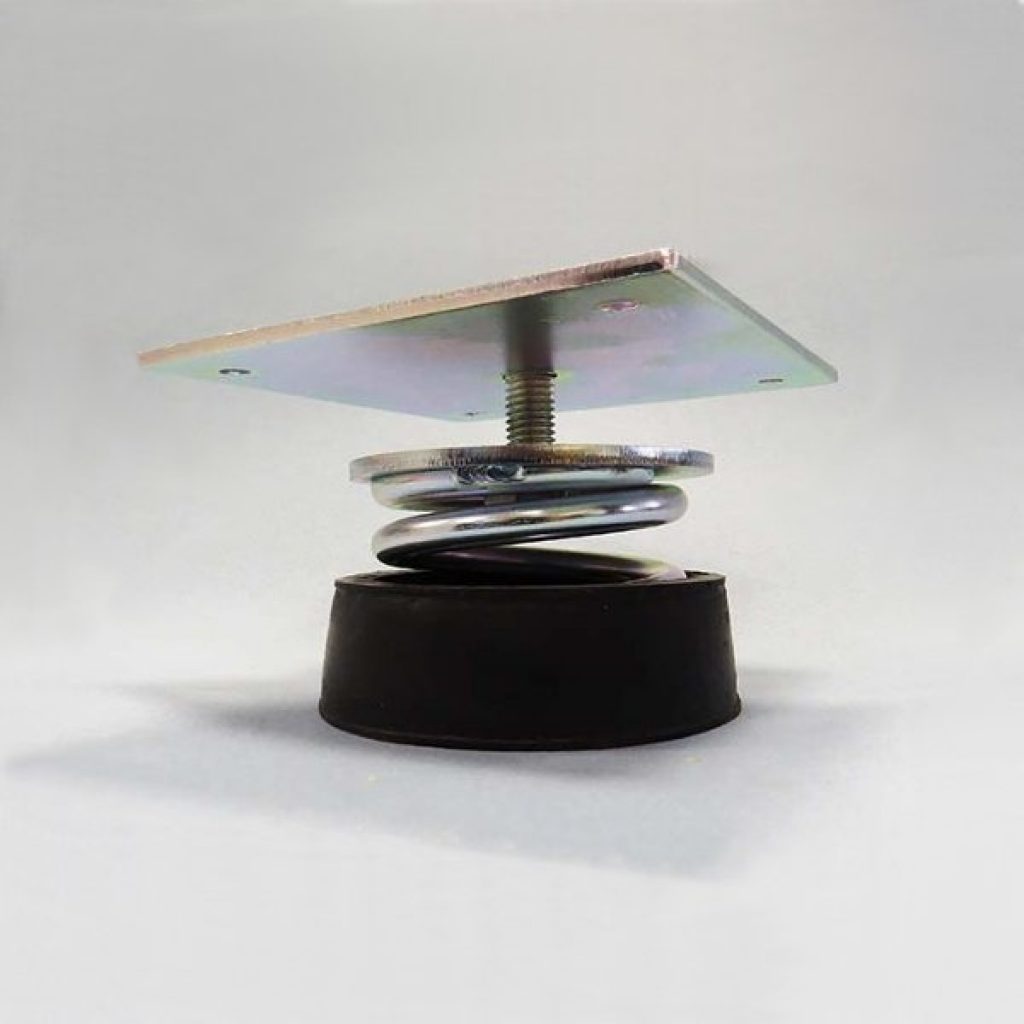

Rubber or spring isolators are used to support a floor made from layers of material. Layers are typically wooden boards, paving slabs or screed. Multiple layers, possibly including batons, are necessary to create a stiff floor and to introduce enough mass to correctly compress the isolator.

Rubber Dry and Formwork Floor Systems

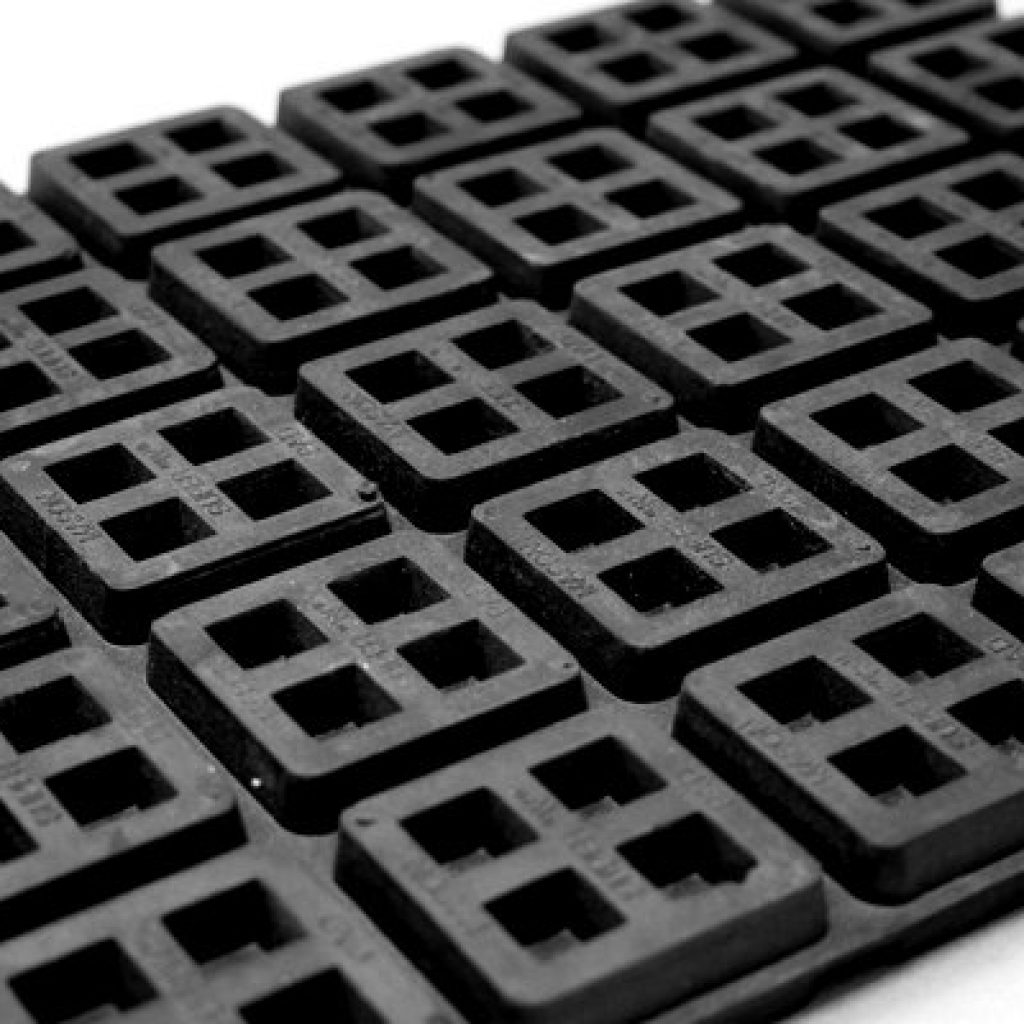

Rubber is the correct choice when isolating against airborne noise sources, such as speech and music. Some applications would be recording studios, cinemas, or auditoria. All Mason U.K. isolators use virgin natural rubber of bridge-bearing quality. Natural rubber provides the best dynamic response of any known elastomer and the Mason formula provides excellent longevity, designed to exceed the life of the building.

Our rubber isolator product range can be seen at the bottom of the page; we have numerous options available to suit a wide range of projects.

EAFM LDS Rubber Dry Boarded Floating Floor

EAFM LDS Rubber Formwork Reinforced Concrete Floating Floor

Spring Dry and Formwork Floor Systems

Springs are required when the noise source has low frequencies, or there are impacts. Some applications such as gym floors, where people are running on treadmills, performing aerobics, dance floors or bowling alleys. Our spring system is compact, effective and can be supplied in an adjustable form to suit boards or batons. If the existing floor is not level, our adjustable system provides a quick, easy way to construct a perfectly flat floating floor with great isolation performance.

MFS Dry Boarded Floating Floor

MFS Coil Spring Formwork Reinforced Concrete Floating Floor

We can help with the design and specification to suit your project.

Please see an installation video for our MFS-AJ Lightweight Sprung Floating Floor system below: