Acoustic Isolation of Bowling Alleys – Floating Floors

Bowling alleys may produce several types of noise that require acoustic isolation. From the lower frequencies of the ball rolling along the lane and the unmistakable clatter as it hits the bowling pins, to the higher frequencies of people moving about, talking and generally enjoying themselves. This noise can be carried around the building in the form of vibration, which requires isolation measures to control and prevent complaint from surrounding tenancies.

The type of vibration isolation you will need will depend upon the surrounding rooms and structures. For example, you may need to isolate only the bowling lanes, or you made need to isolate the entire room using the ‘box in box’ method. You can isolate floors, walls, and ceilings separately, depending on the soundproofing requirements.

Soundproofing Bowling Lanes

Bowling alleys require effective isolation methods, especially when located on upper floors because low frequencies and noise from the dropping and rolling of heavy balls can more easily propagate through the building. You can mitigate the noise from the balls impacting the lane floor, hitting the pins and the motion of the pin setters by using a special floating floor system.

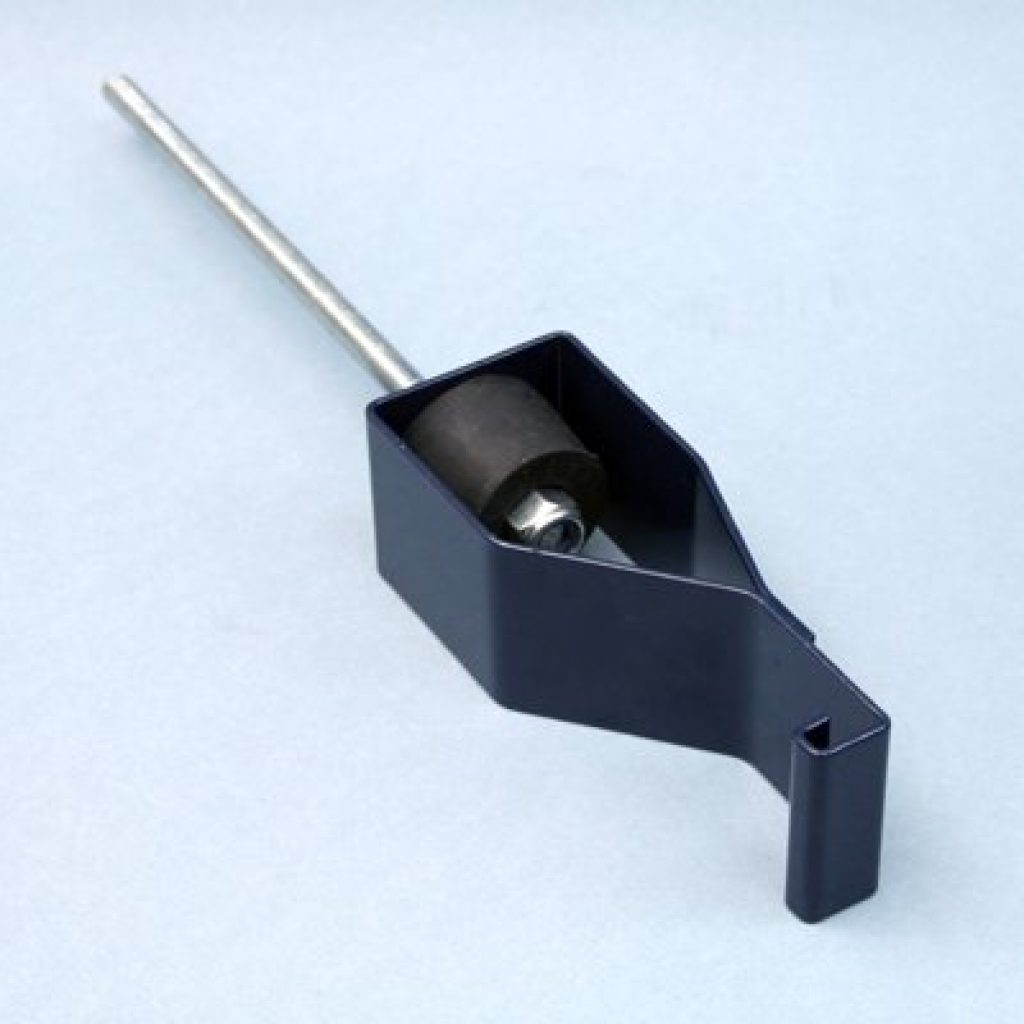

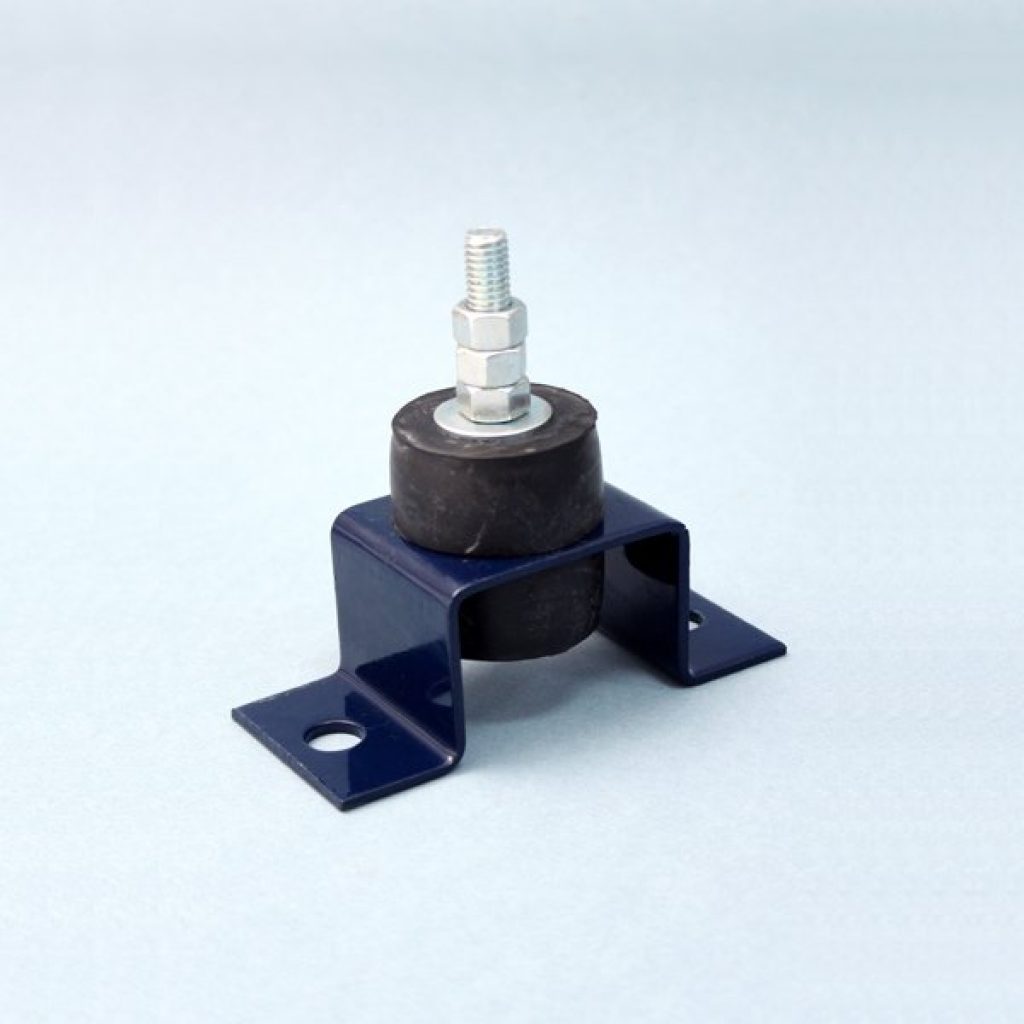

A floating floor helps prevent the vibration caused by the bowling balls passing into the building’s structure, where it can manifest as noise. The floating floor includes metal spring or rubber isolators which absorb the energy from the balls and reduce the overall noise level. Using a jack-up floating floor system is ideal in preventing the vibration caused by bowling activities passing into the surrounding structure.

The design of the floating floor system depends on the requirements of the surrounding spaces and the building’s design.

For example, the design must be tuned to typical bowling vibration sources, and how the building reacts in sympathy. We can help to design a solution to suit both requirements and will work closely with an acoustic consultant to achieve this, which usually involves site testing.

Box-in-box – Total Acoustic Isolation

Sometimes, the main bowling alley room needs a box-in-box structure to isolate an internal room. A box in box design works in a similar way to double-glazing, as it creates an airgap between the internal room and the surrounding structure. This process isolates the floor, ceiling, and walls from the main building using either low dynamic stiffness (LDS) rubber or higher deflection coil springs. This can be essential if significant amplified music is present.

Acoustically Isolated Walls and Ceilings

At times, you may not need a full box-in-box construction, but still need some level of isolation. For example, isolating the ceiling or walls to protect neighbouring rooms or buildings from airborne noise in that direction.

Wall isolation involves completely separating a wall from the rest of the building’s structure. This creates a barrier that dramatically reduces sound transmission. We offer two effective methods for wall isolation.

First, building directly on an acoustic floor eliminates sound transfer through the floor and into the isolated wall. Second, using a wall isolation plate to decouple the wall from the structure and acoustic wall ties to secure it.

The most effective way to isolate against airborne noise passing through ceilings is by using a LDS rubber hanger or spring hangers. These hangers can easily attach to metal frame grid ceiling systems. Drop rods suspend acoustic ceilings from the concrete soffit or timber joists.

By mitigating the diverse types of noise in a bowling alley, you can create a more comfortable and enjoyable environment for bowlers and reduce the impact on the surrounding area.

Mason UK has successfully sound proofed several bowling alleys, including the All Star Lanes at Westfield Stratford City, the largest facility in Europe at the time.

Get In Touch

If you have questions or need more accurate information, you can contact our acoustic engineers. They are friendly and willing to help.