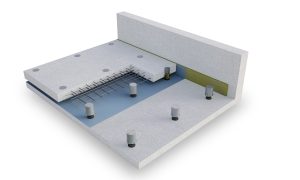

A box in box solution or box in box system is an acoustic engineering solution that creates a room within a room using carefully selected, bespoke acoustic products. This includes a floating floor, a suspended ceiling and isolated walls. With all of these elements in place, the room, or ‘box’, is separated from surrounding structure using spring or rubber isolators, breaking the path for noise and vibration transmission between the room and the surrounding structure of the building.

The box in box solution can be implemented to isolate a room from external sources of noise and vibration, or to isolate the rest of the building from noise and vibration caused by activities within the room itself.

A good example of the former would be a basement that is close to an underground tube line, a very common source of vibration problems in hotels and luxury apartments in London. In a scenario like this, a box in box solution might be specified at the lower basement levels of the building. You might have come across this in the popular BBC documentary, the Mayfair Hotel Megabuild, one of many high-profile projects that Mason has been involved in.

A good example of a box in box solution implemented to isolate the rest of a building from noisy activities within the room itself would be a gym or a nightclub.

An acoustic consultant or vibration control engineer can advise you on whether this approach is necessary for your noise or vibration problem. You can read more about some of the projects Mason has completed where box in box solutions were specified on the projects section of the website.

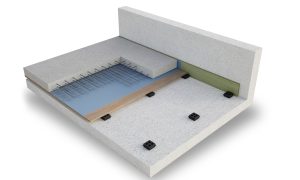

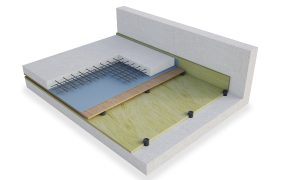

Floating floor:

The centrepiece of a box in a box solution is an acoustic floating floor. There are two main types of floating floor system; concrete floating floors and floor systems comprised of layers of high-strength and mass boarding. Concrete floating floors are used for applications requiring higher levels of acoustic performance and are more common in box in box systems due to greater robustness and isolation performance.

A floating floor achieves acoustic isolation through the creation of an additional floor that is raised from the structural slab beneath using resilient mounts such as spring mounts or rubber isolators. These are carefully chosen based on the application type and specification. This removes the rigid connections from between the floor and the surrounding structure to achieve isolation.

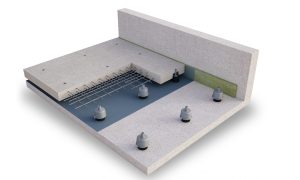

Acoustic Hangers and Isolation Walls

Floating floors are far more common than full box in box systems. A box in box system is only created through the addition of isolated walls and suspended ceilings. Ceilings can be suspended on acoustic hangers, so that the ceiling is supported on spring isolators.

For a box in box solution the walls are ideally built upon the floating floor, ensuring no solid connection between the existing structure and the isolated room.